Anti-explosive Ex

Electrical installations in dangerous areas

Definitions and general information

To carry out this work, standards from Underwriter Laboratories, National Electrical Code, Argentine Institute of Materials Rationalization, D.I.N. have been analyzed, as well as experiences and work guidelines developed for oil and gas companies, distilleries, laboratories, oil companies and other related companies.

First of all, we will introduce ourselves to the subject by exposing the basic criteria for any anti-explosive installation.

Due to the increasing use of electrical appliances and equipment in places where the atmosphere shows signs of danger (because the air may contain elements in suspension that produce flammable or explosive mixtures), it became necessary to develop elements and techniques to ensure their use without danger of possible accidents in the mentioned places or damage to the installations and to clearly determine the different types of environments and classify them according to the elements that make up their atmosphere.

To define what is called “hazardous zone” we must refer to the IRAM IAP A20-1 standard and article 500 of the National Electrical Code, which define it as one in which deterioration may occur in the facilities due to the explosion or ignition of vapors, liquids, gases and dusts, due to attacks by chemical products or the spread of fire, of mixtures of elements contained in the atmosphere.

CLASS I ENVIRONMENT

These are areas where the air contains or may contain gases or vapors in suspension in quantities that can produce flammable or explosive mixtures (acetylene, hydrogen, ethyl ether, gasoline, butane, natural gas, etc.).

DIVISION I

Define places with the following characteristics:

a) Environment with hazardous concentrations of flammable gases and vapours under normal operating conditions.

b) Environment where such concentrations may frequently exist due to loss or repairs.

c) Environment where such concentrations may frequently exist due to loss or repairs.

The places referred to in Class I Division I are those where volatile liquids or flammable liquefied gases are transferred, painting or spraying operations with volatile liquids, dryers with evaporation of flammable solvents, places used for extraction of gases with solvents, laundries that use flammable volatile liquids, gas generating plants with the possibility of leaks, flammable gas pumping rooms and other places where the concentration of flammable gas or steam can acquire dangerous values.

DIVISION II

Define places with the following characteristics:

a) Environment where volatile liquids and flammable gases or vapors are used, processed or manufactured, but they are in closed containers or pipes, from which they can only escape due to an accident, breakage or malfunction of the equipment.

b) An environment where hazardous concentrations of flammable gases or vapors are prevented by forced ventilation, but which, in the event of equipment failure or malfunction, represents a hazard.

c) Locations adjacent to Class I Division I locations, into which flammable vapors and gases may be introduced unless they have forced ventilation with a safety system that prevents failure of the ventilation equipment.

Division II of Class I defines places where volatile liquids, hazardous gases and vapors are commonly used, which represent a hazard only in cases of failures, breakdowns, accidents or abnormal operation of the installations. To delimit the hazardous area in these cases, the quantity of hazardous elements that can escape, ventilation capacity, volume of the premises, etc., must be taken into account.

CLASS II ENVIRONMENT

These are areas where the air contains combustible dust in suspension in quantities that can cause ignition or explosion (aluminum dust, magnesium dust, carbon black, coal dust, coke dust, granulated fluorine dust, etc.).

DIVISION I

Define places with the following characteristics:

a) Environment where under normal operating conditions, there will be periodically or continuously combustible dust in a condition to produce ignition or explosion.

b) Environment where, due to possible malfunctions, malfunction or operation of machines or equipment, flammable mixtures may be produced that may cause ignition or explosion.

c) Places where electrically conductive dust may be present.

Division I of Class II includes in general grain storage plants (silos), pulverizing plants, cleaning plants, mixers, elevators, collectors and all similar dust producing equipment, any place or warehouse where under normal operating conditions there is dust in the air which produces flammable or explosive mixtures; very dangerous dusts are electrically conductive, as are coke and charcoal dusts. Dusts that do not conduct electricity but are combustible are those produced in the handling of grains, cocoa and sugar grinding and any organic material that can produce combustible dusts.

DIVISION II

It considers those places where under normal conditions it is not possible to have combustible dust in suspension in the air but it can affect in the following ways:

a) That the amount of dust deposited is sufficient to prevent heat dissipation from electrical equipment.

b) Dust accumulated on and/or inside the electrical equipment may ignite due to sparks or dust-caused fumes.

The places where these conditions can occur are mainly those neighboring those of Class II Division I, in addition to the places that have conveyors, fans and closed hoppers and equipment where quantities of dust can be released under abnormal operating conditions.

CLASS III ENVIRONMENT

These are areas in which the air contains flammable fibers and volatiles in suspension, but not in sufficient quantities to produce explosive or flammable mixtures.

DIVISION I

These are places where easily flammable fibers and materials that produce combustible volatiles are used or manufactured.

This division includes rayon, cotton and textile mills, carpentries, flax processing mills, etc., in general mills processing easily flammable fibers and volatiles, such as rayon, nylon, cotton, tow, hemp, etc.

DIVISION II

Includes places where fibers and volatiles are stored or handled but are not in the manufacturing process.

ATMOSPHERIC GROUPS

In order to carry out the tests and verifications, atmospheric mixtures have been defined and grouped according to their hazardousness:

Clase I

Group A : with acetylene.

Group B : with hydrogen, lighting gas or equivalents.

Group C : with ethyl ether, ethylene chloropropane.

Group D : with gasoline, butane, propane, alcohol, acetone, natural gas.

Clase II

Group E : with metallic powder of aluminum, magnesium and their alloys.

Group F : with carbon black and coal dust.

Group G : with grain powder: flour, starch, etc.

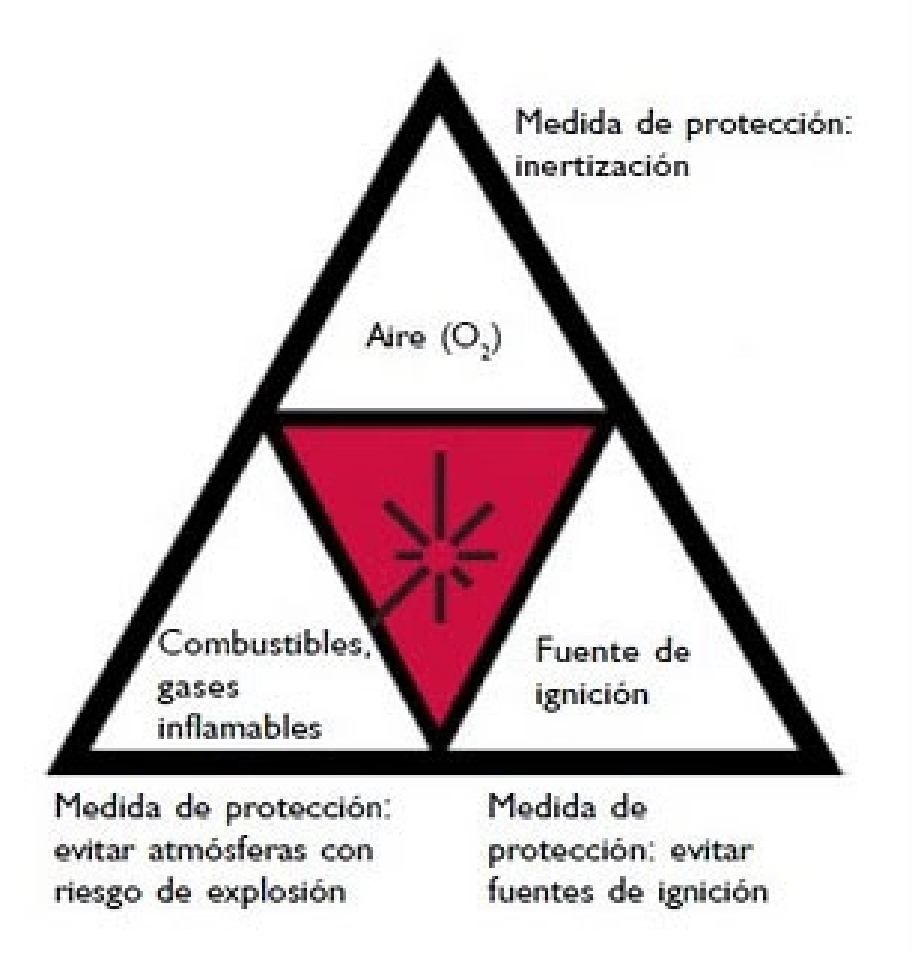

EXPLOSION PROTECTION

Prerequisites for an explosion to occur

The term “explosion” refers to the exothermic reaction with oxygen of a combustible substance or a hazardous and potentially explosive atmosphere, in which a large amount of energy is released.

Depending on the speed of the combustion process, we speak of deflagration, explosion or detonation.

The danger increases with the speed of propagation, with detonation being the most dangerous situation of all.

There is a risk of explosion whenever flammable gases, vapors or dusts are mixed with air or oxygen.

This risk does not only affect chemical or mining industry facilities: a liquor bottling plant with high alcohol content or a grain silo are also potential sources of explosion.

Any uncontrolled explosion poses a potential risk to people's health, physical integrity and life, as well as causing serious material damage.

Combustible substances in the form of gases, vapors, mists or dusts and closely mixed with oxygen create potentially explosive hazardous atmospheres which, in case of ignition, can be dangerous for the safety of persons and the environment.

The ignition energy required varies considerably from one substance to another.

Ignition sources

To ignite a potentially explosive atmosphere requires an ignition source that provides the minimum necessary energy.

Some ignition sources are:

- SPARKS AND ELECTRIC ARCS

- HOT SURFACES

- ELECTROSTATIC DISCHARGES

- ATMOSPHERIC DISCHARGES (LIGHTNING STRIKES)

- SPARKS CAUSED BY FRICTION

- MECHANICS AND IMPACTS

- ELECTROMAGNETIC RADIATION

- ULTRASOUNDS

- ADIABATIC COMPRESSION (SHOCK WAVES)

- IONIZING RADIATION

- OPTICAL RADIATION

- CHEMICAL REACTIONS

- FLAMES.

Secondary explosion protection (Ex) counteracts these ignition sources.

Mixes

The ratio of combustible substance to available air is considered hazardous when it is in the explosion range.

The limits of this range are called upper and lower explosion limits, outside of which no explosion can occur.

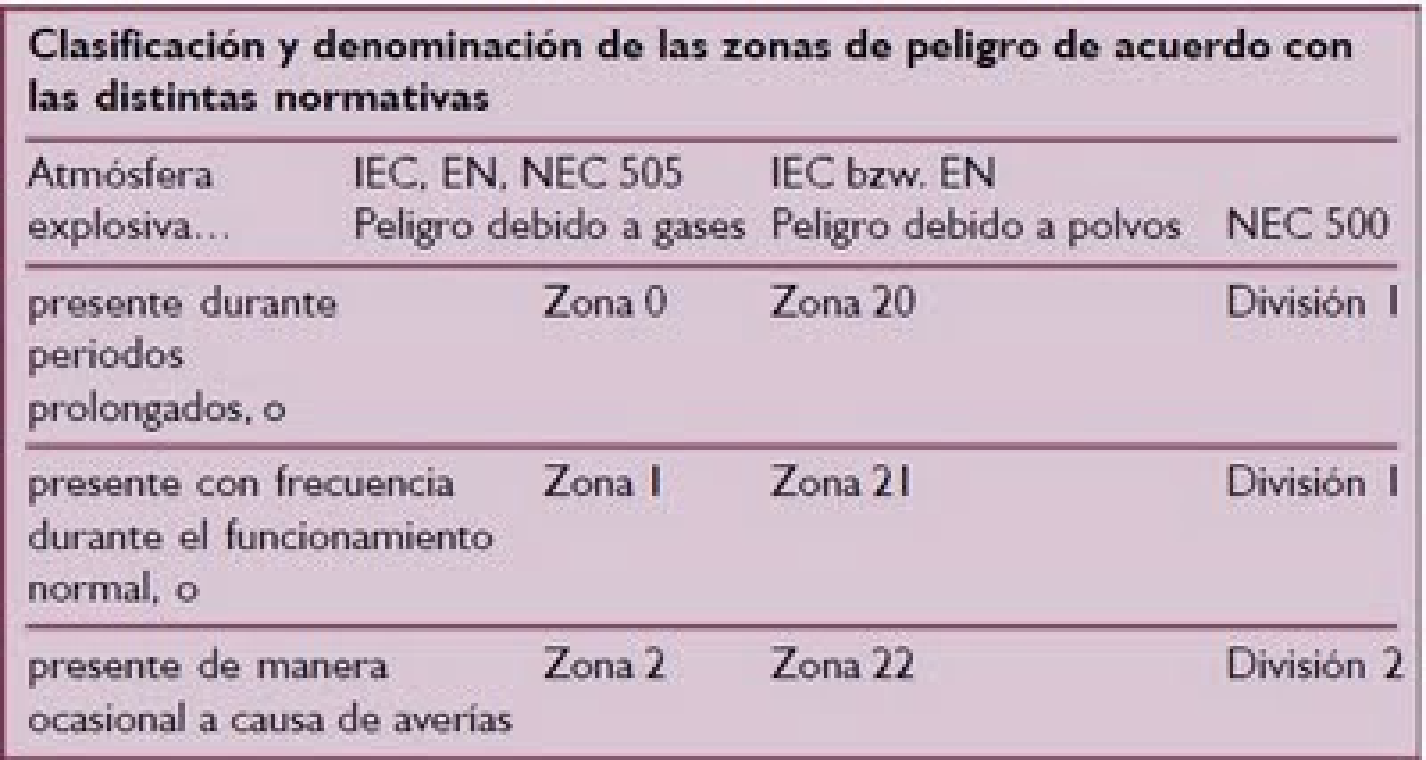

Zones

Areas where there is a risk of explosion are classified into different zones depending on the frequency with which a potentially explosive atmosphere occurs and its duration. There are now regulations that establish the requirements that equipment must meet to be used in these specific areas, as well as methods for verifying its compliance with these minimum requirements.

The definition of these zones provided by Community Directive 1999/92/EC is as follows:

The probability of a potentially explosive atmosphere decreases with increasing distance from the source of the hazard.

For this reason, the area adjacent to Zone 0 is always considered Zone 1, and the area adjacent to Zone 1 is always considered Zone 2. To understand this, nothing better than the example of an airplane refueling: the airplane's fuel tanks are located in the wings, i.e. Zone 0.

In the classification by zones it is necessary to distinguish between gases and dusts, mainly because dust, as it is deposited on a piece of equipment, forms insulating layers that can increase the working temperature of the equipment to dangerous levels.

The US NEC 500 standard, in addition to distinguishing between gases and dust, takes into account different types of fibers.

The following systematization in class I, II and III is quite illustrative.

MEASURES TO PREVENT AN EXPLOSION.

Primary protection against explosions.

Explosion protection (hereinafter referred to as “Ex” protection) is intended to prevent explosions from occurring.

The term “primary explosion protection” refers to all measures that can be taken to prevent the formation of a potentially explosive atmosphere.

Normally, these are measures taken by the operator of the facility:

· Lower the temperature of flammable liquids below their flash point;

· Avoid combustible materials (replacing them with non-hazardous alternatives);

· Inertization (addition of nitrogen or carbon dioxide to displace oxygen from the process);

· Keep the concentration outside the danger limits (see potentially explosive mixtures);

· Natural or technical ventilation.

Secondary protection against explosions.

If the risk of explosion cannot be ruled out or if it cannot be completely eliminated by the primary protective measures, measures must be taken to prevent the ignition of potentially hazardous atmospheres.

To do so, the following must be done:

· Avoid ignition sources.

· Avoid hot surfaces.

· Define rules of conduct for employees and personnel (no open flames, no smoking, no working with angle grinders or welding equipment).

· Tertiary protection against explosions.

If simultaneous ignition sources and explosive mixtures cannot be ruled out, controlled explosions should be triggered or attempts should be made to burn flammable gases before they reach dangerous concentrations.

To prevent personal injury, it is necessary to:

· Prevent the presence of people in the area.

· Adopt special structural measures.

· Ensure that explosions are controlled (e.g., in an encapsulated pressure area).

Source: Fisicanet

This website uses cookies to ensure you get the best experience on our website.