Linear fillers

The precision of our machines.

| Filling range | Tolerance |

|---|---|

| From 50 ml to 1 liter. | +/- 0.2% in 1 liter. |

| From 500 ml to 5 liters. | +/- 0.1% in 5 liters. |

| From 1 liter to 20 liters. | +/- 0.05% in 20 liters. |

| From 20 liters to 200 liters. | +/- 0,03% |

| From 100 liters to 1000 liters. | +/- 0,03% |

Get to know the types of linear fillers

Characteristics of the fillers according to the lines

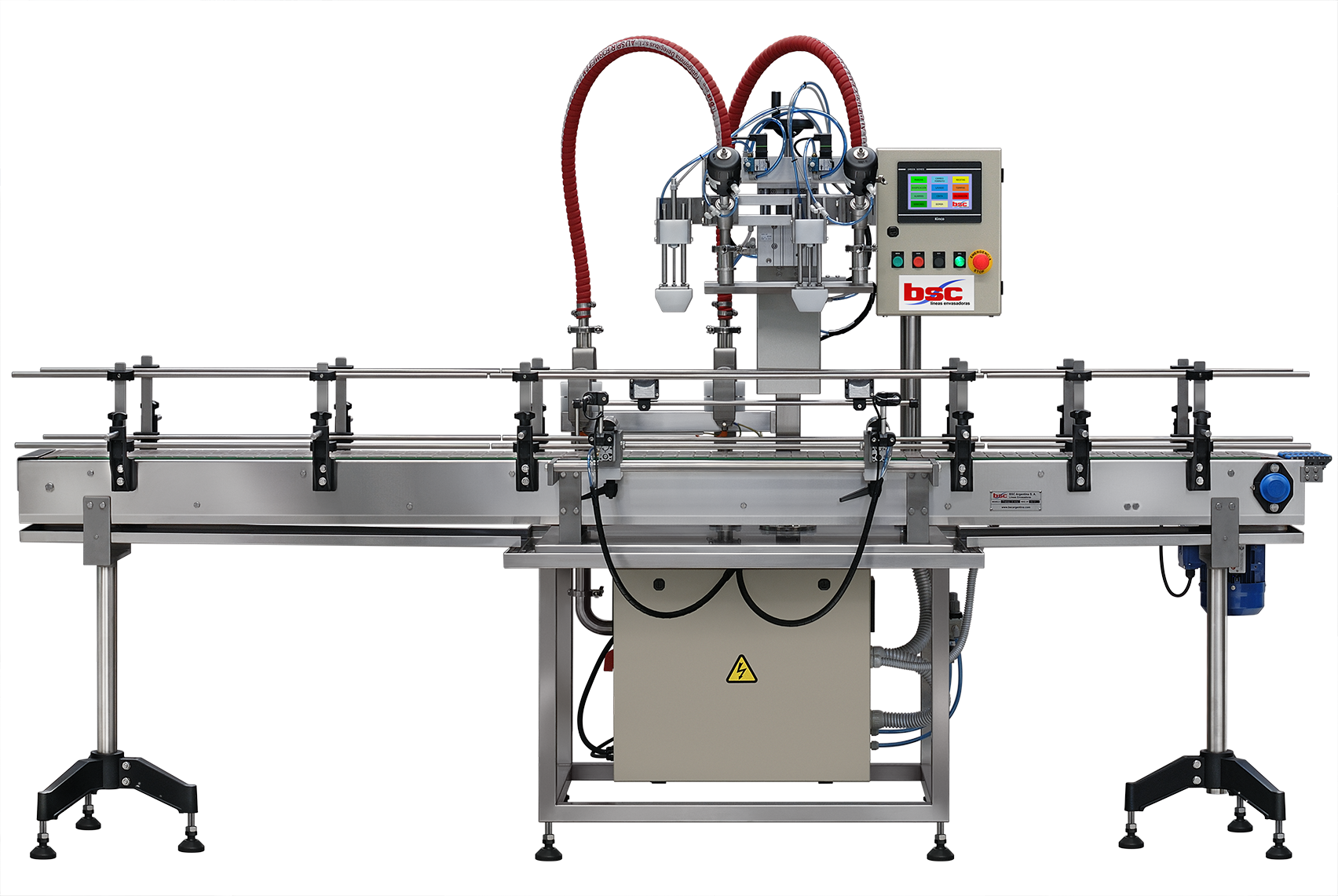

FULL LINE - SERIE LLM

ECO LINE - SERIE LLM-ECO

MODULAR LINE - SERIE LA

Linear fillers are suitable for:

- Foamy, viscous, corrosive, abrasive, flammable, flowable products with solid particles in suspension.

Examples: Mineral oils, paints, isocyanates and solvents, glues and adhesives, waxes, fertilizers, herbicides, seed cures, automotive products, detergents, bleaches.

Format:

- Filling of bottles, cans, drums, cans, drums. Possibility of filling different products in double chamber containers (1+1), by installing 2 parallel filling circuits.

Technical features:

- Robust AISI 304 or AISI 316 stainless steel structure.

- Parts in contact with the products according to their needs (stainless steel AISI 316, PVC, Titanium, EPDM, Viton, Teflon gaskets).

- Operator panel for PLC programming and control of the equipment.

- Safety guards, anti-trapping (FULL LINE AND ECO LINE)

- Electrical and pneumatic elements of leading brands.

Variables:

- L-Mag, volumetric flow meter.

- L-Mass, mass flow meter.

Benefits:

- Temperature range of the product to be filled from -10° C to 125° C.

- Perfect adaptation to all types of liquids.

- Maximum precision and repeatability of dispensed volumes.

- Adjustment and variation of volumes with touch screen and possibility of countless recipes.

- Great versatility in format changes.

- Fast, tool-less format changes.

- Quick adjustment of the different container dimensions and volumes to be dispensed.

- Programmable cleaning speed depending on the products (cleaning quality improved and cleaning times reduced)

- Low quantity of washing liquid.

- Cleaning in place (CIP) and sterilization in place (SIP) as standard (150° C for 60 minutes)

- Simple and linear filling circuit, without mechanical moving parts

The machine in operation

This website uses cookies to ensure you get the best experience on our website.